In an era where efficient fuel management is vital for various industries, selecting the appropriate Fuel Transfer Pump has become a critical decision for businesses to ensure operational efficiency and cost-effectiveness. According to a recent report by Grand View Research, the global fuel transfer pump market size was valued at approximately USD 2.37 billion in 2022, with expectations to expand at a compound annual growth rate (CAGR) of 4.9% from 2023 to 2030. This growth is driven by the increasing demand for fuel-efficient solutions and the rising focus on safety standards in fuel handling processes. As businesses look to invest in reliable fuel transfer systems, understanding the nuances of selecting the best manufacturer is essential.

This guide navigates the key considerations in choosing high-quality Fuel Transfer Pumps that align with specific operational requirements, ensuring both safety and efficiency in fuel transfer operations.

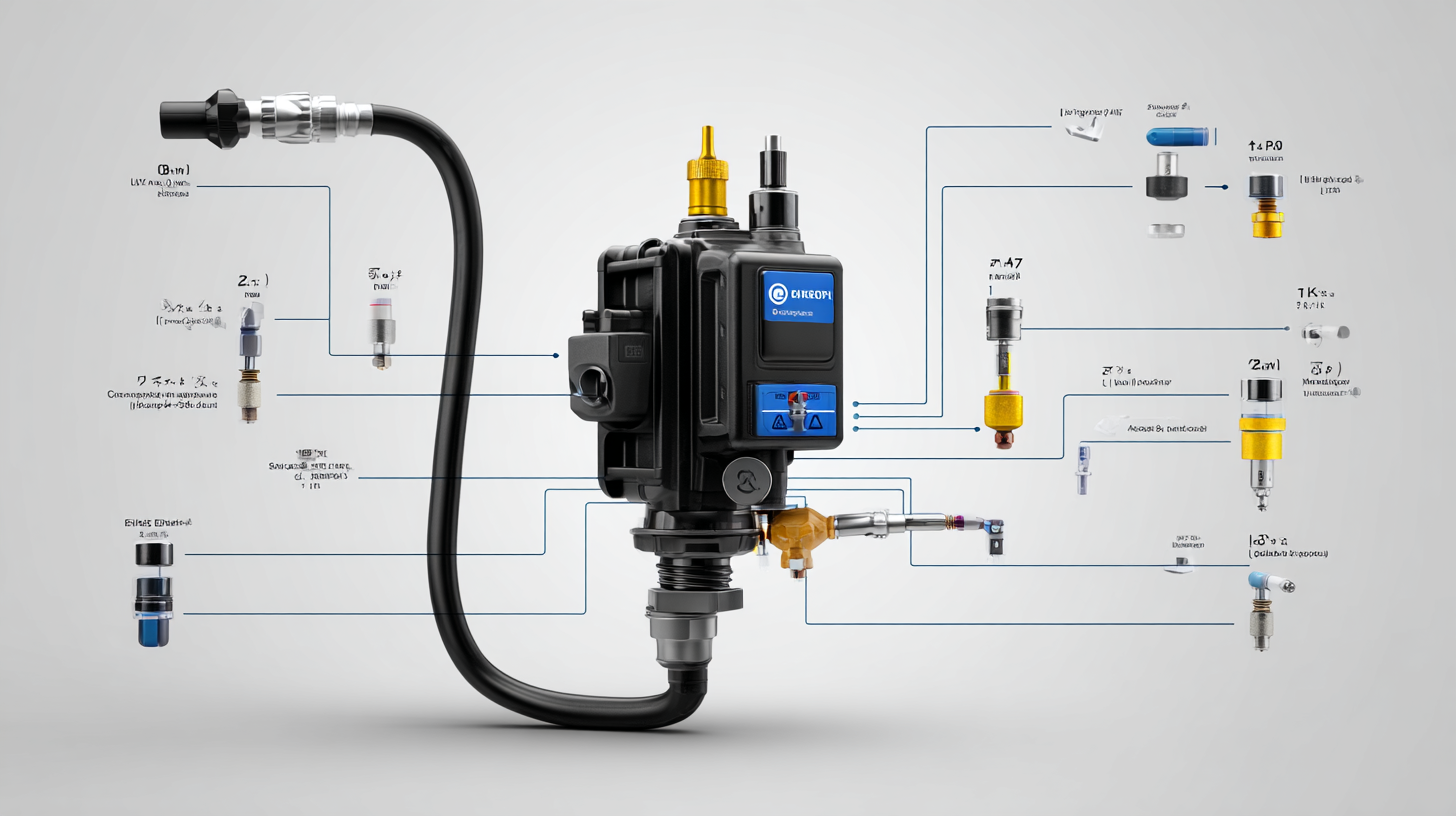

When selecting a fuel transfer pump, several key factors must be considered to ensure optimal performance and reliability. The first factor is the pump's flow rate, which typically ranges from 10 to 120 gallons per minute (GPM) depending on the application. For instance, high-efficiency pumps with flow rates exceeding 30 GPM are ideal for large-scale operations, while lower rates are more suited for personal use. Coupled with this is the pump's power source; electric pumps offer convenience but may limit mobility, while gasoline-powered versions excel in portability.

Another vital consideration is compatibility with various fuels and liquids. Many pumps are specifically designed for diesel, gasoline, or biofuels. According to a systematic literature review focused on greenhouse gas emissions in transport, the improper selection of fuel pumps can significantly inflate operational costs and increase emissions. It is crucial to choose a fuel transfer pump that aligns well with your fuel type to avoid degradation of components and ensure environmental compliance. Keeping these factors at the forefront of your decision-making process will lead to better efficiency and sustainability in your operations.

When selecting the best fuel transfer pump for your needs, understanding the different types available is crucial. Fuel transfer pumps are primarily categorized into AC (Alternating Current) and DC (Direct Current) models, each offering unique features tailored for specific applications. AC pumps are typically used in bulk fuel transfer scenarios, delivering high flow rates suitable for commercial use. In contrast, DC pumps are more portable and often utilized for smaller, localized applications, making them ideal for regular consumers or small businesses.

According to a recent market analysis, the automotive fuel transfer pumps sector is projected to experience significant growth, escalating from a valuation of USD 2.1 billion in 2024 to an estimated USD 3 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.1% during the period. This increase emphasizes the increasing demand for efficient and reliable fuel transfer solutions, driven by factors such as the burgeoning automotive industry and a rising emphasis on sustainability in fuel usage.

Therefore, when choosing a fuel transfer pump, consider both the operational requirements and the future trends in the fuel market to make the most informed decision.

When selecting a fuel transfer pump, determining the right flow rate is crucial to meet your specific needs. The flow rate, typically measured in gallons per minute (GPM), dictates how quickly fuel can be transferred from one location to another. To identify the ideal flow rate for your applications, consider the size of your tanks and the volume of fuel you need to move. For instance, if you’re dealing with a large tank and require rapid transfers, a higher flow rate pump will be necessary. On the other hand, smaller operations might find a lower flow rate sufficient, allowing for precise control and minimizing spillage.

Additionally, it’s essential to evaluate the use case scenarios where the pump will be employed. If you're transferring fuel frequently or require immediate access during high-demand times, opting for a pump with a robust flow rate can enhance efficiency and reduce downtime. Conversely, if your needs are sporadic or involve sensitive equipment, a lower flow rate pump may better suit your operations. By analyzing these factors, you can ensure that the fuel transfer pump you choose aligns perfectly with your workflow, maximizing performance and convenience.

When selecting a fuel transfer pump, safety features should be a top priority. Given the increasing market for mobile fuel pumps, projected to grow significantly over the next decade, understanding these safety elements becomes essential for both personal and family protection. Gasoline is highly flammable, presenting considerable risks if not handled correctly. Therefore, any fuel transfer pump should come equipped with automatic shut-off mechanisms, leak detection systems, and overfill protection. These features not only mitigate the danger posed by gasoline but also ensure a safer fueling process.

Recent advancements and revised standards in the industry have further highlighted the importance of safety. For instance, new regulations now mandate improved designs for in-tank fuel pumps and fuel hoses. This is crucial, as any compromise in these components can lead to severe accidents. Additionally, many manufacturers are incorporating durable materials and innovative designs that enhance safety, such as crash-resistant features for specialized applications. Prioritizing these safety characteristics in fuel transfer pumps will ultimately contribute to a safer environment for everyone involved in the transfer and use of fuel.

| Pump Type | Flow Rate (GPM) | Maximum Pressure (PSI) | Power Source | Safety Features |

|---|---|---|---|---|

| Electric | 20 | 50 | AC | Overload Protection, Leakage Detection |

| Hand Pump | 5 | N/A | Manual | Non-Sparking Mechanism |

| Diesel Transfer Pump | 40 | 60 | DC | Auto Shut-Off, Anti-Static Features |

| Pneumatic Pump | 15 | 30 | Air | Pressure Relief Valve, Spark-Free Operation |

| AC Powered Pump | 25 | 70 | AC | Overheat Protection, Emergency Stop Button |

Proper maintenance is essential for extending the life of your fuel transfer pump. Regularly inspecting the pump for any signs of wear and tear can help identify potential issues before they become major problems. Checking for leaks is crucial; even small leaks can lead to significant fuel loss and damage over time. Additionally, keeping the pump clean from dirt and debris will ensure that it operates smoothly. Use a soft cloth to wipe down the exterior regularly, and ensure any filters are replaced as needed.

Another important aspect of maintenance is monitoring the pump's performance. Pay attention to any unusual noises, changes in pressure, or fluctuations in flow rate. These could indicate that the pump requires servicing or that parts are wearing out. Lubricating moving parts according to the manufacturer’s recommendations can also prevent unnecessary friction and wear. Furthermore, ensuring that the pump is stored in a temperature-controlled environment when not in use will help mitigate damage from extreme temperatures, thus prolonging its lifespan. By following these maintenance tips, you can ensure that your fuel transfer pump remains efficient and reliable for years to come.