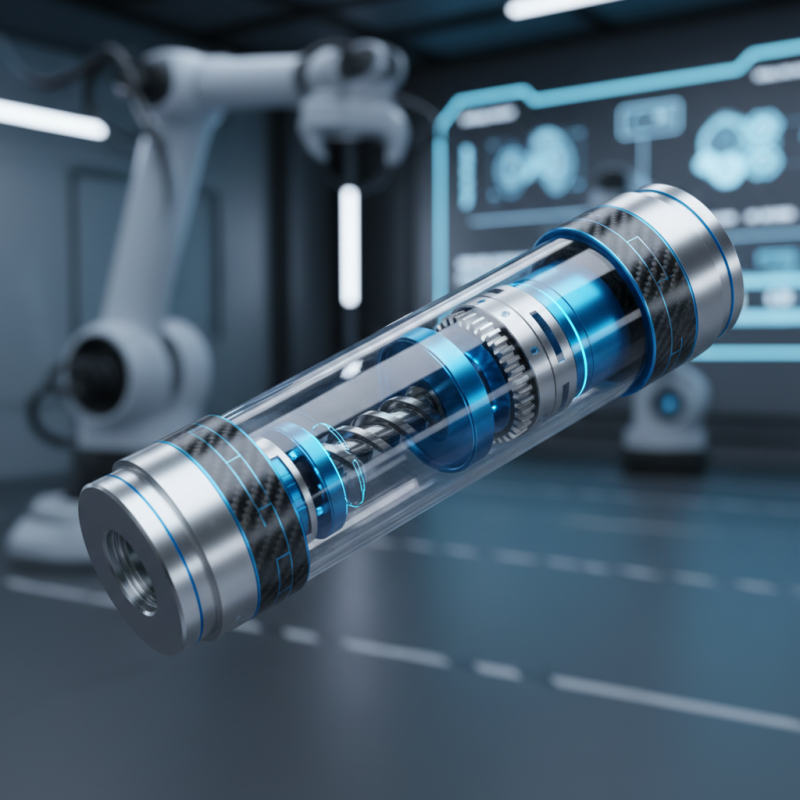

The Steering Cylinder plays a crucial role in vehicle control and maneuverability. As the automotive industry evolves, understanding the features of steering cylinders becomes essential. In 2026, advancements in technology will reshape how these components function.

New materials and design innovations promise increased efficiency and durability. However, not all models may meet the growing demands for performance. For instance, some steering cylinders may lag behind in responsiveness or stability.

Exploring the key features of steering cylinders is vital for consumers and manufacturers alike. Knowing what to look for can enhance safety and driving experience. It’s important to consider both the advantages and shortcomings of new designs as they emerge. Being informed will help in making better choices in an ever-changing market.

The steering cylinder plays a critical role in vehicle dynamics. Its main function is to convert rotational motion into linear force, enabling precise steering control. According to industry reports, a well-designed steering cylinder can improve vehicle handling by up to 30%. This highlights its importance in ensuring safety and stability.

Efficiency is key. A typical steering system experiences some wear over time, reducing performance. Studies indicate that as much as 15% of steering force can be lost due to inadequate cylinder maintenance. Regular upkeep is essential. Neglecting this can lead to compromised vehicle control, and in extreme cases, accidents.

Consider the materials used. Advanced alloys and composites enhance durability, but they can increase costs. Striking a balance between cost and quality is crucial. Engineered solutions may not always be perfect, and challenges with heat dissipation can occur. Continuous improvement in design and maintenance protocols needs to be prioritized for optimal performance.

| Feature | Description | Importance |

|---|---|---|

| High Pressure Resistance | Ability to withstand high hydraulic pressures during operation. | Critical for ensuring safe and effective steering performance. |

| Durability | Resistant to wear and tear, ensuring long service life. | Reduces maintenance costs and increases reliability. |

| Lightweight Design | Constructed with lightweight materials for improved vehicle efficiency. | Enhances fuel efficiency and handling. |

| Easy Installation | Designed for quick and easy mounting to the vehicle. | Saves time and labor during assembly. |

| Corrosion Resistance | Coated to resist rust and environmental damage. | Prolongs the lifespan of the cylinder in various environments. |

| Precision Engineering | Manufactured to tight tolerances for optimal performance. | Ensures smooth and accurate steering control. |

| Adjustable Settings | Allows customization of steering responses. | Improves user experience based on personal preference. |

In 2026, steering cylinders will feature advanced designs aimed at improving safety and performance. Enhanced durability is crucial. Materials used will affect the longevity and wear resistance of these components. Optimized shapes and sizes also play a role. They can improve responsiveness during operation.

Another key design element is the incorporation of smart technology. Sensors in steering cylinders can provide real-time data. This data could help with diagnostics and maintenance. Drivers might receive alerts about potential issues. Smart features can also enhance user experience. They can offer more precise control of the vehicle.

Although these advancements are promising, challenges exist. Manufacturers must ensure that innovation doesn't come at the expense of reliability. Testing for various conditions is essential. Many designs may look great on paper but fail in real-world applications. Continuous feedback from users can guide these improvements. It’s essential to prioritize both performance and practical use in everyday driving scenarios.

Modern steering cylinders play a crucial role in vehicle control. The materials used in their construction greatly influence durability and performance. Common materials include aluminum, stainless steel, and advanced composites. Each material has unique benefits and drawbacks. For instance, aluminum is lightweight but may corrode over time. In contrast, stainless steel offers better corrosion resistance, yet it is heavier and more expensive.

According to a recent industry report, nearly 25% of steering cylinder failures are due to material fatigue. Designers must consider environmental factors as well. High temperatures can weaken aluminum. In regions with extreme weather, this can be a significant issue. The choice of seals and coatings also impacts longevity. A study revealed that the right seal can extend cylinder life by up to 40%. However, many manufacturers still overlook this aspect.

It's essential to delve deeper into end-user feedback. Some users report unexpected failures even in high-quality cylinders. Understanding these experiences can help improve future designs. The constant evolution in material science presents both opportunities and challenges. Companies must balance cost, weight, and durability effectively.

In 2026, steering cylinders are witnessing remarkable innovations. These advancements enhance vehicle performance and safety. For instance, the integration of smart sensors allows for real-time feedback. This technology is intended to improve driver control and vehicle response. Sensors monitor conditions and adjust steering efforts accordingly. It's a leap towards more adaptive driving experiences.

The design of steering cylinders is changing too. New materials are lighter, yet stronger. This shift reduces the overall weight of vehicles. As a result, fuel efficiency improves significantly. However, some engineers express concerns about durability. The impact of lighter materials on long-term performance is still under observation.

Moreover, electric steering systems are becoming prevalent. They offer smoother operation and reduced maintenance needs. Yet, reliance on electronics raises questions about reliability in extreme conditions. Drivers may question how these systems perform under stress. Continuous testing is necessary to ensure safety and performance. Innovations in steering cylinder systems for 2026 imply exciting possibilities, but challenges remain to be addressed.

Steering cylinders are vital for maneuverability in various vehicles. To ensure optimal performance, regular maintenance is essential. Start by checking fluid levels. Low fluid can lead to inadequate steering response. Inspect the seals and connections for leaks. A small leak can quickly become a bigger problem.

Cleaning the exterior components is equally important. Dirt and debris can accumulate, affecting functionality. Use a soft cloth to wipe down the surfaces. It's easy to overlook this step, but it makes a difference. If the cylinder is exposed to harsh conditions, consider more frequent cleaning.

Listen to the sound of the steering action. Unusual noises can indicate issues. Don't ignore them. They might be subtle but worth investigating. Lastly, a regular visual inspection can reveal wear and tear. Addressing minor issues early can prevent costly repairs later. Remember, maintenance is an ongoing task. Treat it as a priority, not an afterthought.

This bar chart displays the top features of steering cylinders for 2026 based on various criteria. Ratings are on a scale from 0 to 10, showcasing durability as the most highly rated feature, followed by performance and ease of installation.