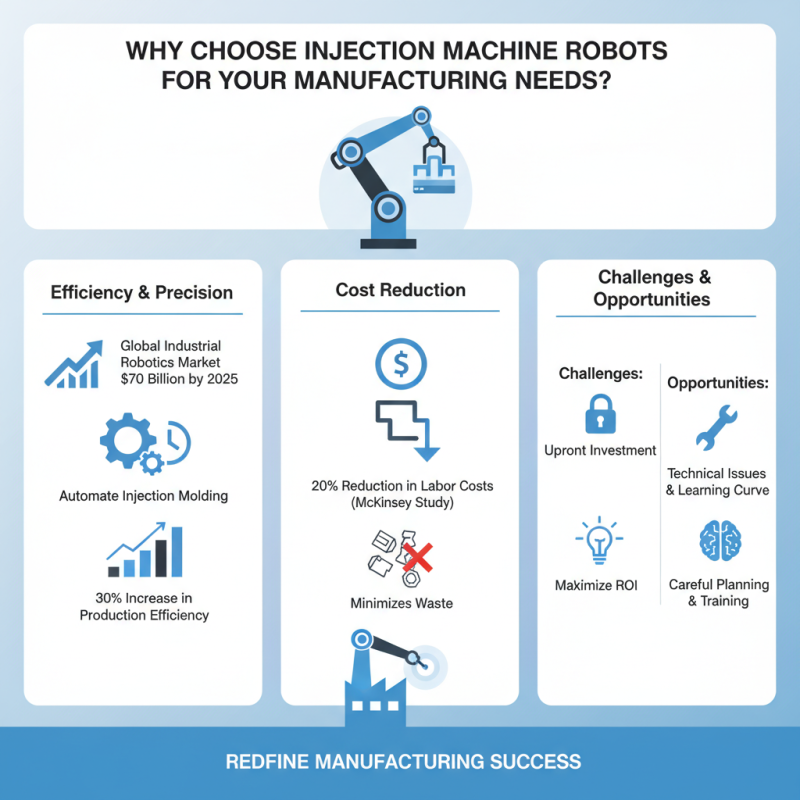

In today's competitive manufacturing landscape, the demand for efficiency and precision is at an all-time high. According to a report by Grand View Research, the global industrial robotics market is projected to reach $70 billion by 2025. As manufacturers seek to enhance productivity, Injection Machine Robots emerge as a compelling solution. These robots automate the injection molding process, reducing cycle times and minimizing waste.

Adopting Injection Machine Robots can lead to a 30% increase in production efficiency. A key insight from a McKinsey study indicates that companies integrating automation see, on average, a 20% reduction in labor costs. However, the transition to robotic systems isn't without challenges. Manufacturers must consider the upfront investment and potential technical issues. Companies may struggle with the initial learning curve, which can impede seamless integration.

Investing in Injection Machine Robots presents a unique opportunity. While the benefits are profound, businesses must approach the change thoughtfully. Careful planning and training are essential for maximizing the return on investment. The journey towards automation is complex, yet the rewards can redefine manufacturing success.

Injection machine robots are transforming the manufacturing landscape. These advanced machines offer numerous advantages that can enhance production efficiency. According to a report by the International Federation of Robotics, automation in manufacturing can increase productivity by up to 30%. This substantial gain is crucial for companies striving to remain competitive.

One major advantage of injection machine robots is precision. These robots deliver consistent quality with minimal human error. Studies show that achieving a defect rate of less than 1% is possible with robotic processes. This level of accuracy reduces waste and maximizes resource utilization. However, it’s essential to evaluate whether existing staff can effectively manage these systems. Machines can malfunction, and human oversight remains vital.

Tips: Regular training for operators can ensure effective machine management. Also, conduct routine maintenance checks to prevent unexpected downtimes. Consider implementing a gradual integration of robotics to allow for necessary adjustments.

Another benefit is flexibility. Injection machine robots can adapt to various tasks. They can switch between products quickly, which is essential in dynamic markets. However, the initial investment can be high, and some may find ROI challenging to measure. Adjusting to this new workflow takes time and may require a cultural shift within the organization.

Injection machine robots are transforming manufacturing processes. They offer precision, speed, and consistency. According to industry reports, automation can increase production efficiency by 20% to 30%. This boost stems from their ability to minimize human error and optimize cycle times.

Key features include advanced sensors and real-time monitoring. These robots adapt quickly to changes, ensuring that production remains efficient. It is crucial, however, to continually assess the effectiveness of these technologies. Some manufacturers still experience downtime due to maintenance issues. A report showed that 15% of automated lines face unexpected halts. These interruptions highlight the importance of regular evaluations.

Flexibility is another strong point. Injection machine robots can switch between different tasks effortlessly. This capability brings versatility to production lines. Yet, integrating new technology can pose challenges. Employee training is necessary to ensure smooth transitions. A study indicated that 40% of workers felt unprepared after automation was introduced. Balancing innovation with workforce readiness remains a key consideration in manufacturing.

Manufacturers continuously seek ways to cut expenses. Injection machine robots offer a solution. These robots automate tasks, reducing labor costs significantly. A report from the International Federation of Robotics suggests that automation could lead to a 30% reduction in production costs.

Efficiency is also about speed. Robots operate faster than humans. They can cycle through tasks with minimal downtime. This speed translates to increased output. A study found that companies using robotic automation reported an average productivity boost of 20%. However, initial setup costs can be high. Not all companies see immediate returns. Transitioning to automation requires careful planning.

Employee training becomes essential. Staff must adapt to new technologies. There might be resistance to change. Some workers fear job displacement. Addressing these concerns is crucial. Companies should focus on upskilling their workforce. Balancing automation with human labor can lead to a more efficient environment.

Injection machine robots play a vital role in enhancing product quality within manufacturing processes. According to a recent report by the International Society of Automation, companies using robotics have seen a 20% reduction in defect rates. This improvement results from the robots’ precision and consistency. They maintain tight tolerances, ensuring that every product meets quality standards.

Additionally, using injection machine robots can minimize the risk of human error. A survey by the Manufacturing Institute revealed that 75% of manufacturers believe automation helps reduce mistakes. Despite these benefits, some manufacturers still hesitate to adopt this technology. They worry about the initial investment or fear potential job losses. However, embracing automation can lead to higher productivity and ultimately, quality improvements.

Moreover, regular maintenance and updates for these robots are necessary. Without proper care, robots can underperform. A report by the Robotics Industry Association highlighted that up to 30% of robotic systems are not utilized to their full capacity. This underutilization often stems from poor training or lack of resources. Manufacturers must address these challenges to fully leverage the benefits of injection machine robots for better product quality.

The injection molding industry is evolving rapidly. According to the latest report from the International Federation of Robotics, the use of robotics in manufacturing is expected to grow by 30% by 2025. Injection machine robots are at the forefront of this innovation. They help streamline production processes, reduce waste, and enhance efficiency. These robots can perform complex tasks with high precision and speed, unlike traditional methods.

Future trends indicate a rise in collaborative robots, or cobots. These robots can work alongside human operators, improving safety and productivity. A report from McKinsey highlights that integrating cobots could boost manufacturing efficiency by up to 30%. However, companies need to consider their workforce. Not all employees feel comfortable around robots. Training staff is crucial to maximize potential.

Data from industry analysts suggests that by incorporating AI, injection machine robots will offer even greater adaptability. This flexibility effectively meets various product demands. Companies must be ready for this change. They should reflect on their current skills and technology investments. Balancing automation with human oversight remains a challenge that cannot be ignored.

This chart illustrates the expected growth in the adoption of injection machine robots across various manufacturing sectors from 2023 to 2027, highlighting the potential impact on efficiency and productivity.